The use of automated tools, such as CNC routers, 3D printers, and laser engravers are becoming more and more popular in many maker’s shops as they become much more accessible price wise. They can offer great advantages in doing complex tasks hands free on their own.

Because of this it can be tempting to “set and forget” as they process the job at hand which can sometimes take many hours to complete.

However walking away from these devices and leaving them unmonitored can be a safety risk. Due to how these machine work there is always the potential for fire if something were to go wrong, so we must remain diligent in their use and properly monitor them during any work. Even a CNC router can kindle a fire if something were to fail or jam (an actual case recently discussed in the CNC Router Tips FaceBook group).

Always have a fire extinguisher close at hand if the worst were to happen. Being able to quickly contain a small fire can result in preventing possible major disasters. Be sure to have the right type of extinguisher for your shop needs. https://en.wikipedia.org/wiki/Fire_extinguisher

Smoke detectors can be a bother in a shop, since dust and incidental smoke can set them off, however they offer good early warning for any issue that may happen in the shop when you are not directly there. There are different types of smoke detectors, and the best for a workshop is the photoelectric type. They detects smoke entering the device when it deflects a beam of light, and, unlike the ionization detectors, are less likely to be triggered by only a minor amount of smoke in the air. Try and mount them away from the highest areas of dust to reduce false activation.

Also when using automated system also be sure to wear the proper PPE (personal protective equipment) for the job and make sure it is up to date and in condition for use. While you may not be operating the tool directly you still can be injured if something were to break or from dust and debris. Gear like eye protection for possible impact and laser light, dust masks and respirators, are key to keeping you safe while working. Ear protection can often be overlooked but with loud high pitch machines like CNC routers they are important to protecting your hearing for years down the road. Some materials can also give off harmful dust or gasses when being machined, so be sure to read up on the material properties before working.

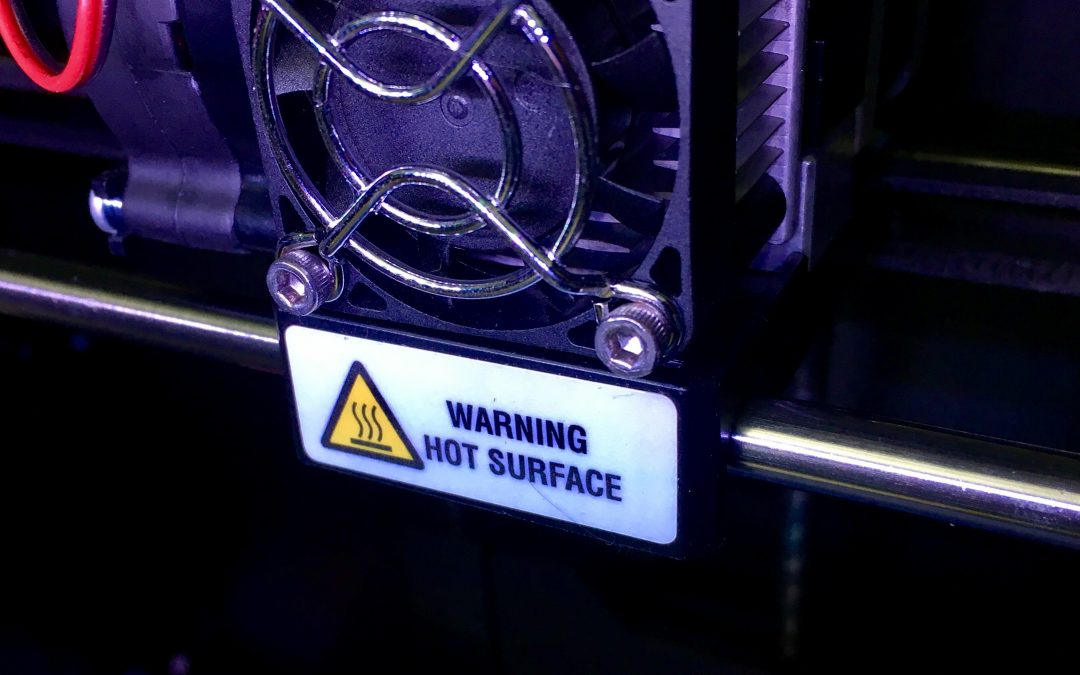

Limiting access to the machines is also important, especially if children are around. These devices have hot, sharp, moving parts and laser beans can damage the unprotected eye. You don’t want someone accidentally walking in near a machine in operation.

The shop is meant to be a fun productive place where we often get away from the world and relax, just be sure to keep safety in the loop as well, especially when the machines are in control. A small accident could damage your machine, a more serious one could injure someone or result in the loss of your shop, home, or even life. #safetyfirst