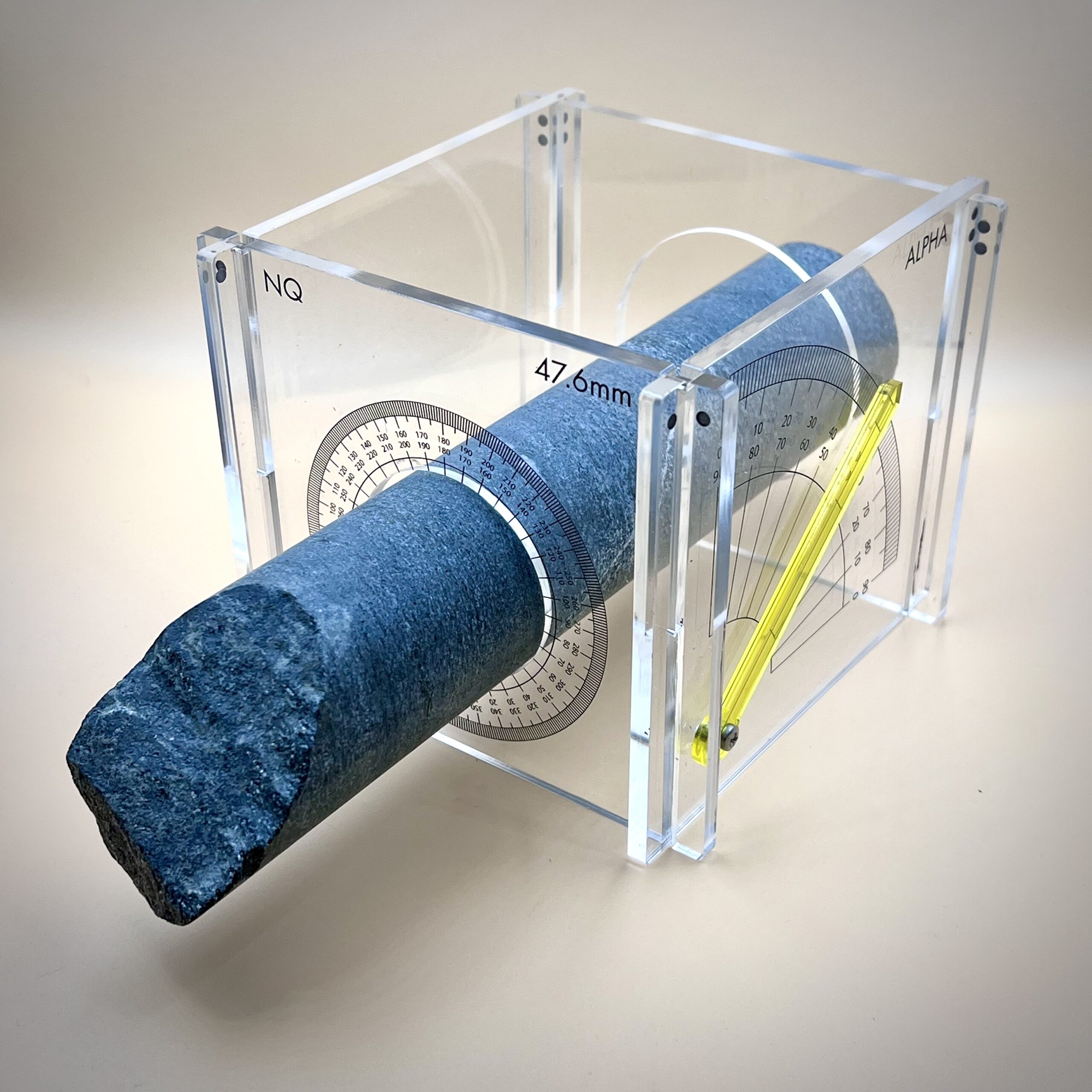

Oriented Core Goniometer

Status: Completed

Last Updated: Jan 4 2024

When we receive an email out of the blue that asks “Could you make this?” our interest is peaked! This was recently the case with one of our aerial imaging clients, that works in the geotechnical industry, who also knew we did CNC and related custom work. The request revolved around a device for measuring the angles of fractures and other features in a mining drill core samples relative to its orientation, known as a Core Goniometer.

With little more than a couple reference photos and a general description, we said yes we would take a look, and the research started. After a few internet searches and reading, we quickly came up with a sketch of the device and translated that into an Illustrator diagram ready for laser cutting.

The item would be made from clear acrylic, similar to existing commercial units. The Trotec Speedy 100 laser offered the quickest and simplest means to prototype the unit in short order. From initial email through research, design, and laser cutting were under 4 hours. Not bad for something we had never heard of prior.

The prototype was reviewed via email and then the first hand with the client. With feedback for changes and adjustments, we were on to version 2, making the device smaller as well as more flexible for use with different core sizes, something most commercial units did not allow.

With the addition of a custom sleeve to store and protect the device, it was completed and delivered to the client for use in the field within 2 days of the initial request.

Now available for purchase via our Etsy store – https://www.etsy.com/ca/listing/1636367494/oriented-core-goniometer