When working with a CNC router one of the key elements of proper setup is secure holddown of the material. There are a number of methods of doing this from vacuum tables, clamps, screws, etc, all with their own pros and cons, and can vary based on the type and size of material being worked.

Our current preferred method is with double sided tape. While this is not a unique or new approach, it does come with some issues. Often times the residue of the tape is left behind on the material and the spoil board making for additional cleanup work.

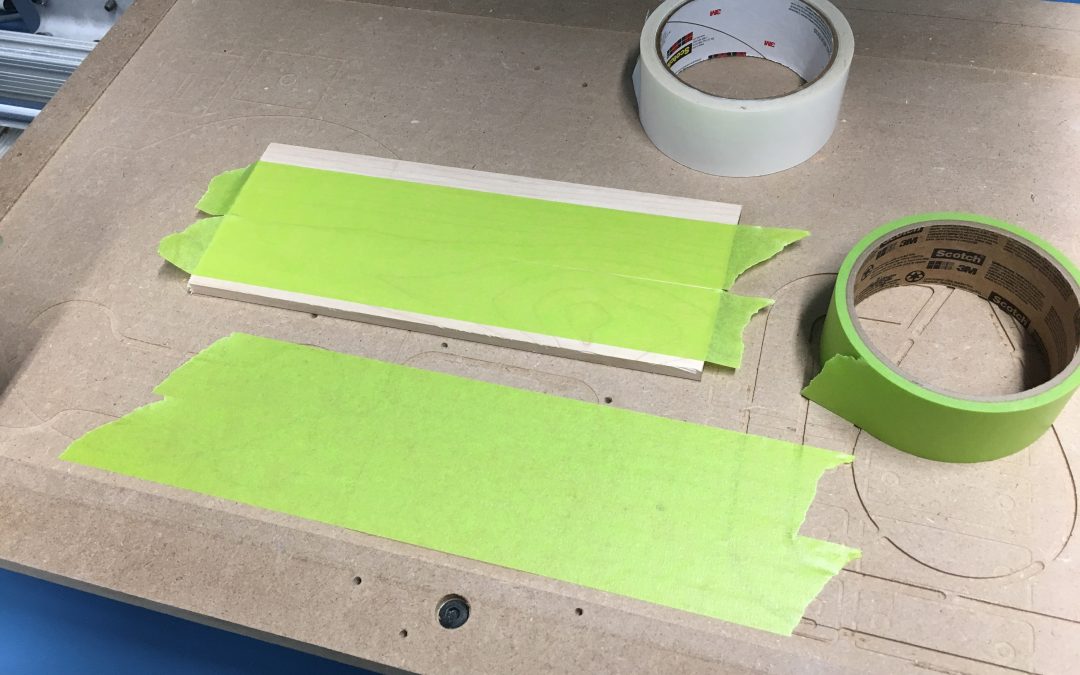

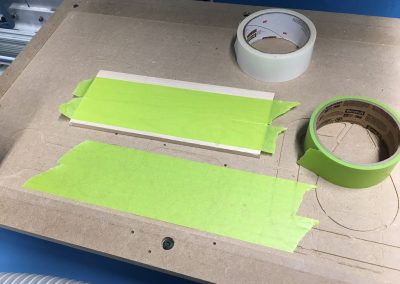

To address this problem we take a slightly different approach, with painters tape being used in a sandwich between the double sided carpet tape, which protects both the router surface and material.

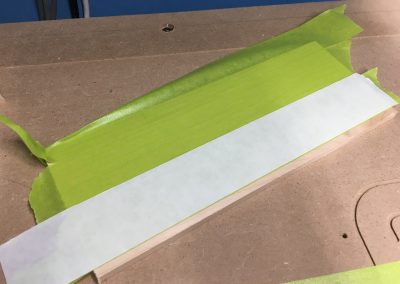

Painters/masking tape is applied to both the bottom of the material and the top of the spoiler board. The double sided tape is then applied to one of the surfaces and the material placed and seated into position.

After the CNC operations are completed the material can then be fairly easily pried free with a scraper or putty knife and the painters tape easily removed taking with it the more adhesive and harder to remove double sided tape.

The tape approach is best suited to smaller items, and has the added advantage of not requiring the use of tabs, which require additional cleanup of the work piece, as the entire part and cuts are all held in place across the bottom surface of the material.

One item of note if cutting deeper than the material thickness is that the tape may cause some gumming up of the bit, so try and avoid over cutting when using this method or position the tape in areas where there are no full cuts to be made.